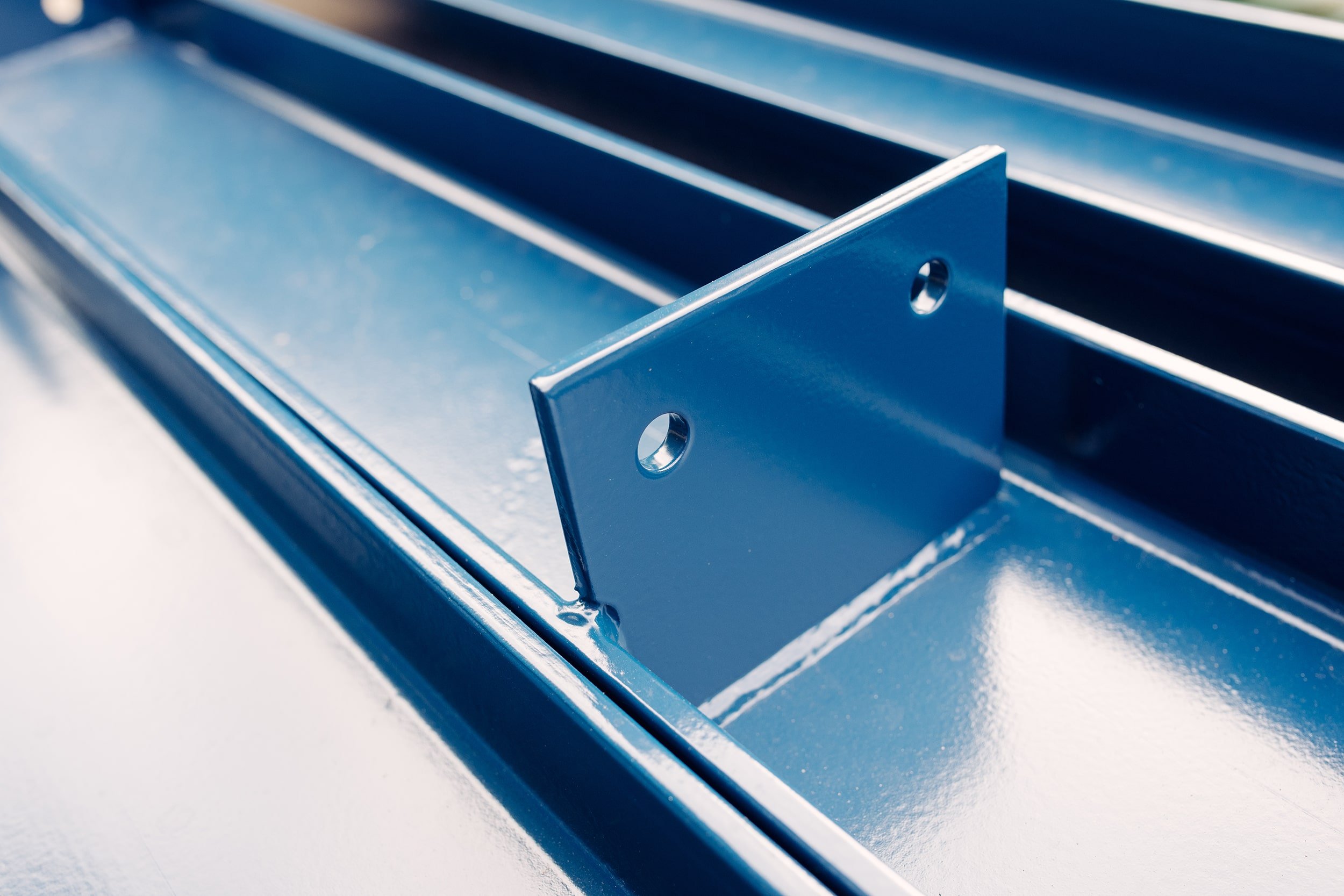

FABRICATION

-

CPM employs skilled trade-qualified boilermakers, welders, and apprentices, specializing in crafting metal components from mild steel, aluminum, and stainless steel. Our in-house expertise allows us to handle diverse workloads, meeting Australian standards. Quality management ensures client satisfaction, backed by assembly services when required.

PROCESSING

-

CPM offers in-house plate processing with a 6KW fiber optic laser cutter, 250T press, and plate rollers. This equipment allows us to manufacture quality parts with control over cost, lead time, and quality. Our services include cutting, pressing, and rolling mild steel, stainless, and aluminum, available as a standalone or integrated service.

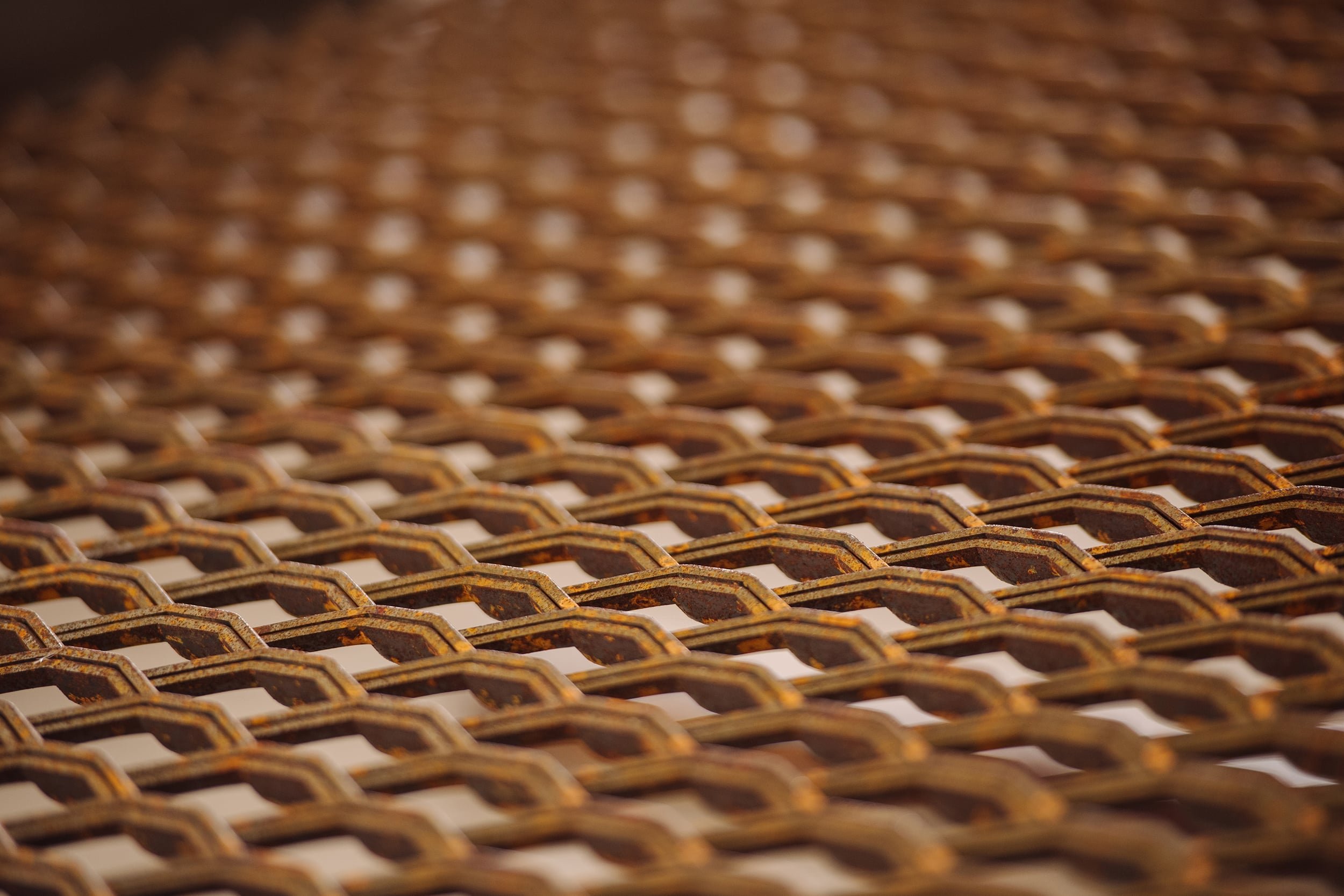

SURFACE TREATMENT

-

CPM operates an industrial paint shop with abrasive blasting and wet spray capabilities. Our rigorous quality assurance ensures consistent, high-end surface treatment for jobs of all sizes. Full traceability and quality records accompany every application.

HYDRAULICS

-

In-house, CPM excels at hydraulic repairs, offering services such as hose repair, manufacturing, fault finding, component supply, and machinery and cylinder servicing. For manufacturing projects, we supply fitted mechanical components ready for use.

Leadership

In 2009, Jason McPherson assumed sole ownership of CPM Engineering, and under his visionary leadership, the company has flourished to become one of the largest and best-equipped fabrication shops in our region.

About CPM Engineering

Complete Precise Manufacturing (CPM) Engineering: Your Trusted Partner in Metal Fabrication, Surface Treatment, Fitting & Machining, and Hydraulic Equipment Services

Founded in 2005 by Jason McPherson and his business partner, CPM Engineering is a proudly Australian, privately owned company. What began as a two-man maintenance team has since evolved into a thriving manufacturing powerhouse, consistently employing over 35 dedicated professionals.

Today, the company stands as a testament to our unwavering commitment to excellence in every facet of our operation.

Embracing Innovation

At CPM, we embrace innovation as the cornerstone of our success. In 2022, we made a significant stride by investing in cutting-edge technology, acquiring a state-of-the-art fiber optic laser cutter.

This strategic move is just the beginning as we continue to explore automation and emerging technologies to propel us into the future.

By harnessing these advancements, we enhance productivity while maintaining our unwavering commitment to uncompromised quality. The result? A premium manufacturing service that's second to none.

Our Vision

Our mission at CPM Engineering is to simplify our clients' procurement process. We provide a comprehensive suite of services that seamlessly complement each other, eliminating the need to engage multiple contractors.

Whether it's manufacturing high-precision components, surface treatment, or partial/complete assembly, we offer an all-in-one solution.

Say goodbye to the hassle of sourcing multiple subcontractors. With CPM Engineering, you save valuable time and resources, reducing the complexity of your projects and ensuring the highest quality standards are met.

Why Choose CPM Engineering

End-to-End Solutions: We handle every aspect of your project, from start to finish.

State-of-the-Art Technology: Our continuous investment in cutting-edge technology ensures top-tier results.

Quality Assurance: We uphold the highest quality standards throughout every stage of production.

Efficiency and Cost Savings: Streamline your procurement process, saving time and money.

Experienced Team: Our team of over 35 skilled professionals is committed to your success.

Discover the CPM Engineering advantage - your partner for complete, precise manufacturing solutions.